Memorial Garden IV

Since I finished the concrete model last time, I evaluated the feasibility of the model for the project. From material and aesthetical perspectives, I think it has no big difference from the monuments from the Soviet period. Therefore, I started seeking more innovative materials and an alternative design plan.

Fortunately, I found a material called 'translucent concrete'. It is a type of concrete with optical fibres inside, and the optical fibres can make the concrete translucent if the piece of concrete is big enough. It is not a high-tech material and has been used in the architectural field for decades. For instance, at the 2010 Shanghai Expo, translucent concrete was used in the Italy Pavilion on a relatively large scale.

Translucen concrete

I thought it was an ideal material for the project when I first saw it because I initially wanted to blend the element of light into the design. In the first concrete model, I embodied light with a shape, and their effects were not that good. However, with the material, I can express the symbolic meanings of the light in totally different ways. So I watched the making tutorials online and prepared to make it immediately.

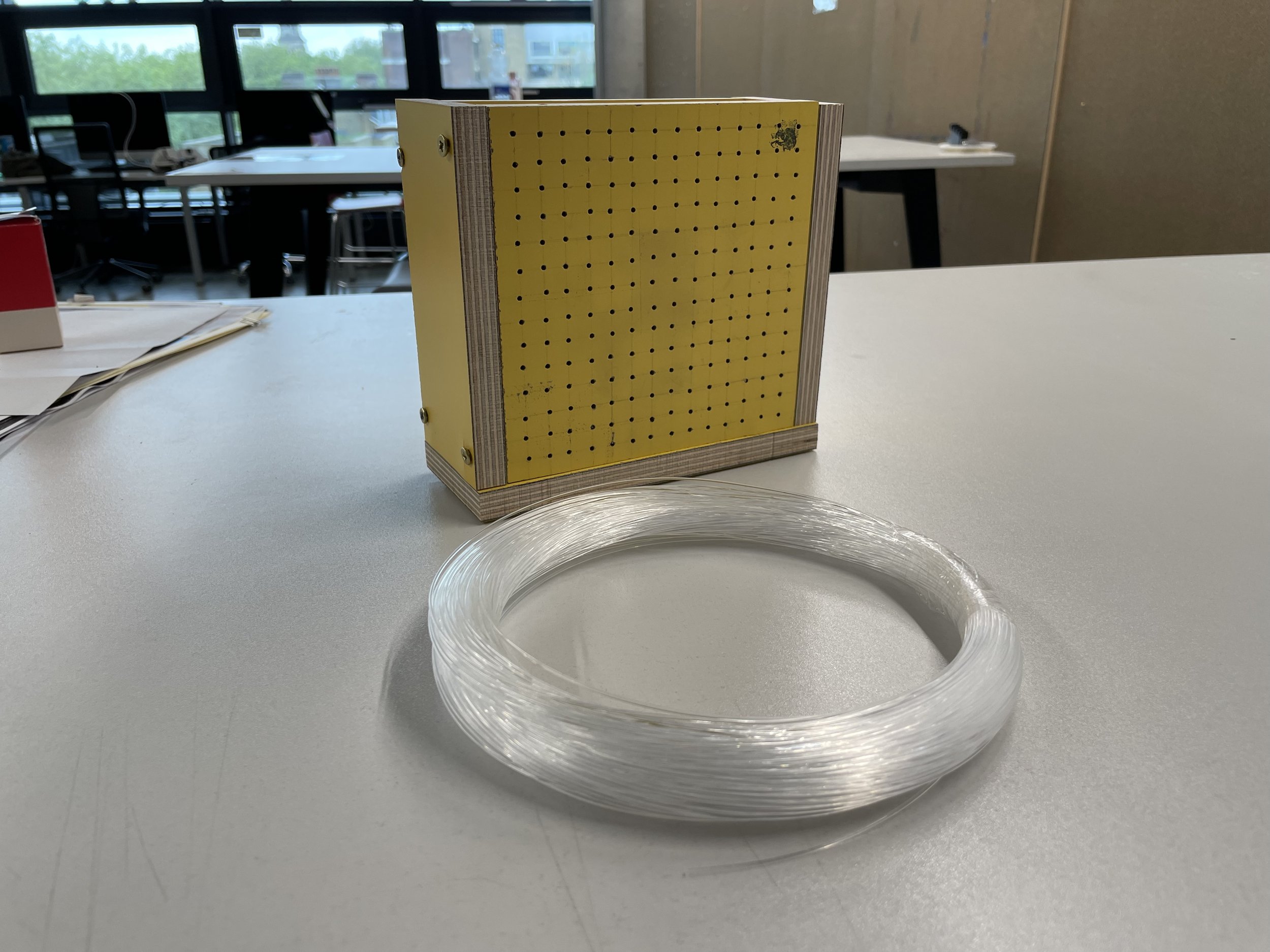

Mould and optical fibre

Mould and optical fibre

I made a concrete casting mould. First, I drilled many holes in the front and back boards, and tried to pull the optical fibres through the boards, then poured the liquid cement into the mould. Processes finished smoothly so far, however, I was trapped by the demoulding step. Due to there being too many optical fibres on the boards, they were stuck in the holes of the boards. Furthermore, the boards were too thick and it made the contact area of boards and fibres too large, leading to the concrete being difficult to separate from the mould.

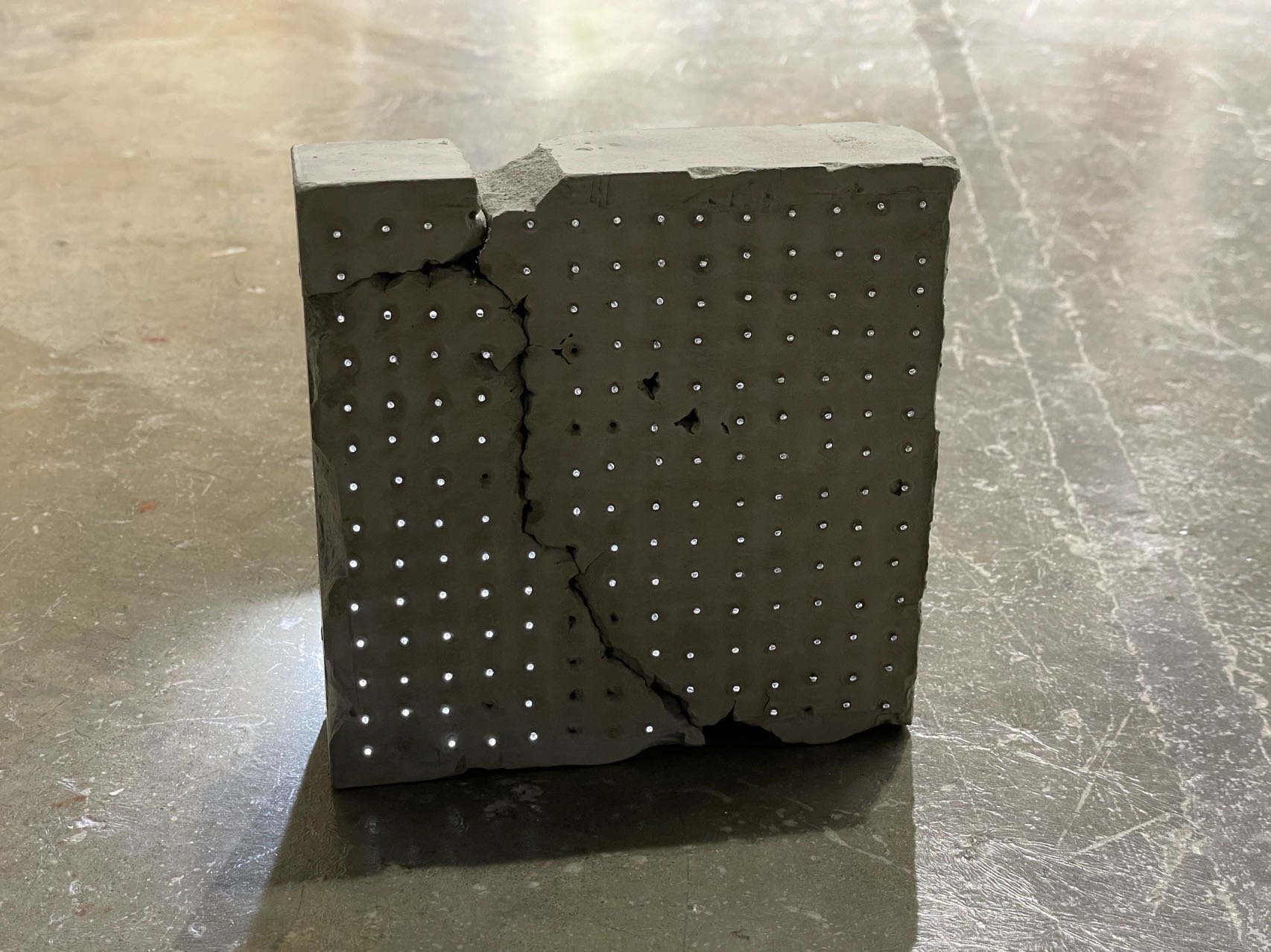

Cracked concrete

I tested the light transmission of the piece of concrete despite it cracked. Fortunately, the effect is just like I assumed, it has some transparency even for this little piece. I decided to make another piece of it. I planned to increase the density of optical fibre and shrink the diameter. Hopefully, in this way, I could get a better light transmission of translucent concrete.

Light transmission testing

Light transmission testing

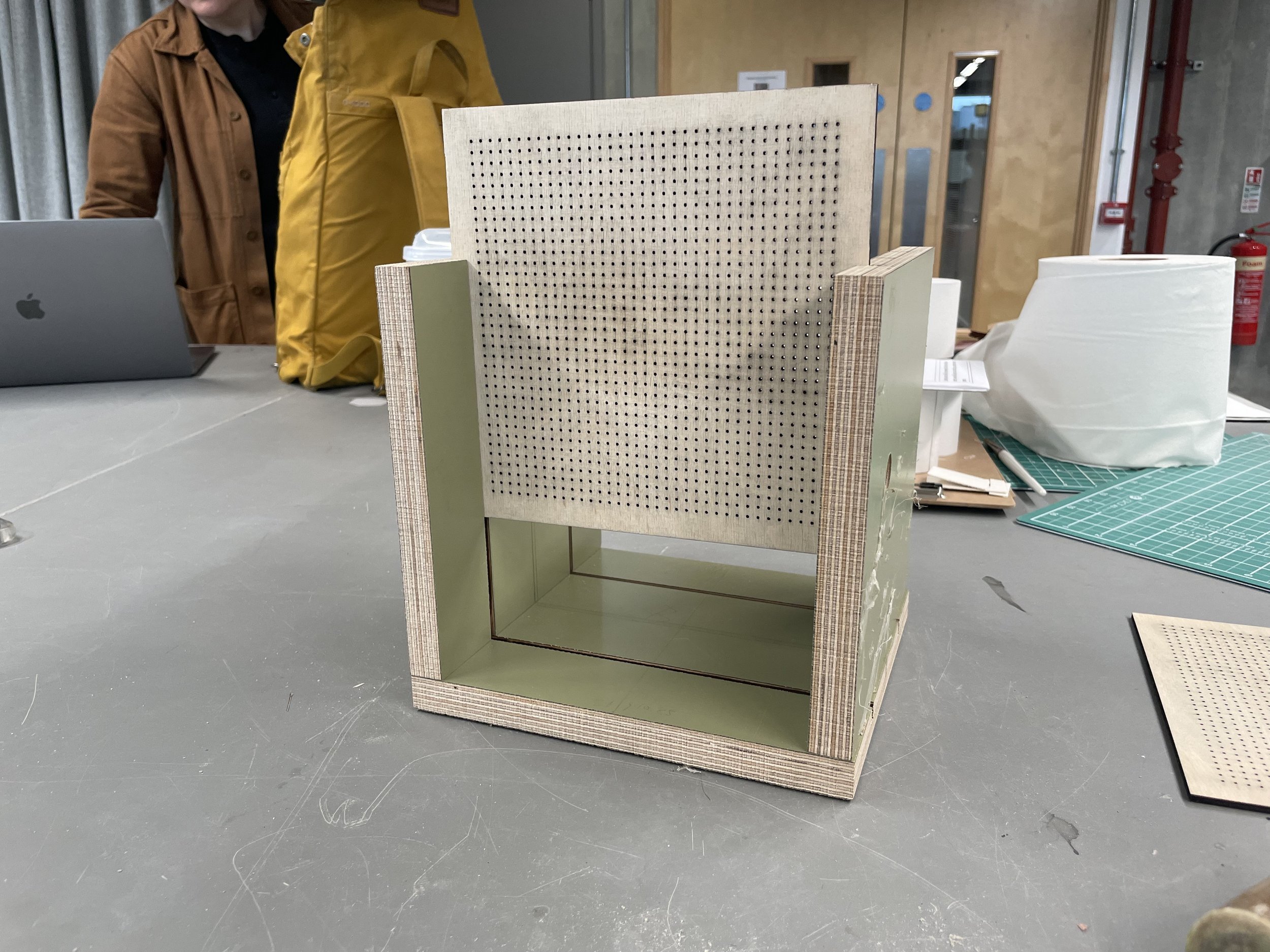

I redesigned the mould and changed the front and back boards of it. I adjusted the thickness to thinner ones to avoid optical fibres stuck in the boards. Moreover, I drilled holes using laser cutting instead of a hand drill this time, which I did manually last time, to get a more even pattern of optical fibres on concrete.

Refined mould

Refined mould